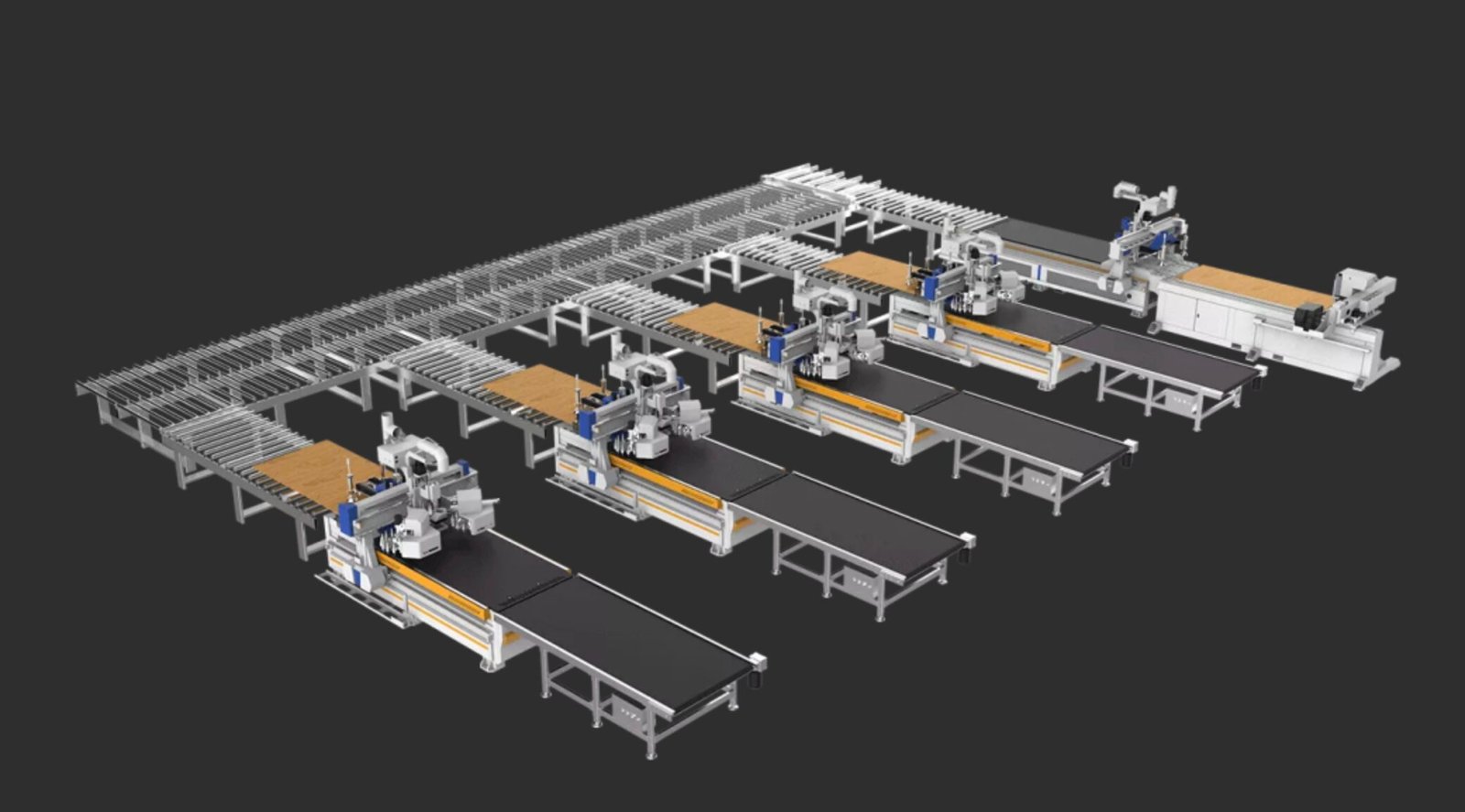

Optimize Your CNC Workflow with Precision and Confidence

Ensure smooth transitions from design to manufacturing with our expert S2M (Screen to Machine) Assistance services. We help you configure and fine-tune every aspect of your S2M (Screen to Machine) — from labeling and tooling to post modifications — ensuring accurate machining output and error-free production.

What We Offer

Our S2M (Screen to Machine) Assistance services empower woodworking and cabinetry businesses to achieve peak CNC performance through tailored setup and optimization. From tool path efficiency to precise labeling, we ensure your entire workflow is production-ready.

Tooling Configuration & Setup

Tooling Configuration & Setup – Define and organize tools for optimal cutting, drilling, and routing performance.

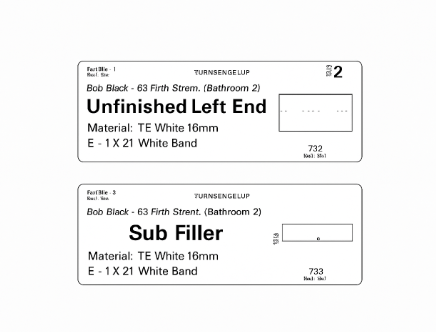

Labeling Customization

Labeling Customization – Create clear and efficient labeling for easy tracking and assembly.

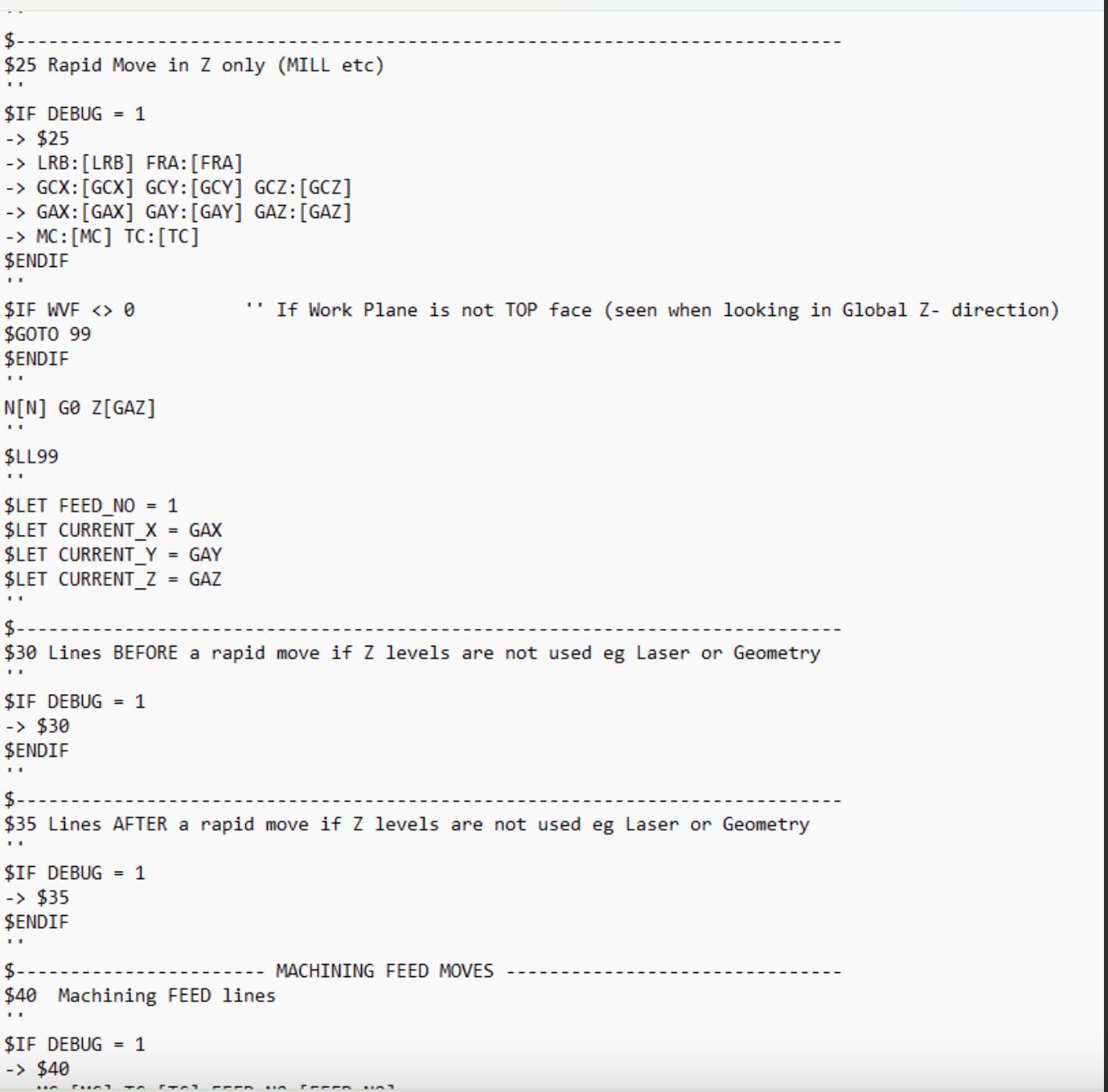

Post Processor Modifications

Post Processor Modifications – Customize outputs to match your machine requirements.

CNC Workflow Optimization

CNC Workflow Optimization – Align every output parameter to ensure smooth, efficient machining.

By bridging the gap between digital design and physical manufacturing, FURNiGENCE helps you achieve faster machining cycles, higher precision, and reduced production errors.

Why Choose FURNiGENCE?

Tailored S2M Setup

Configurations aligned with your specific CNC machines and production needs.

Improved Accuracy

Eliminate output errors and ensure precision in every operation.

Seamless Integration

Ensure flawless communication between CABINET VISION and your machines.

Increased Efficiency

Optimize tool paths and minimize downtime for consistent results.

Our Process

Requirement Analysis

Understand your CNC setup, tooling requirements, and output formats.

Configuration & Setup

Define labeling, tooling, and post parameters within S2M Center.

Testing & Validation

Run test jobs to ensure accuracy and compatibility.

Optimization

Fine-tune configurations for maximum performance and reliability.

Handover & Support

Deliver finalized setups with documentation and ongoing assistance.

Our Commitment

Precision-driven S2M configurations for reliable machining

Streamlined CNC setup for consistent quality

Transparent process and expert technical guidance

Adherence to best practices in design-to-manufacturing automation

Align Your Design-to-Production Workflow with FURNiGENCE S2M Assistance

Get expert configuration, seamless integration, and unmatched CNC precision — all tailored to your workshop’s needs.